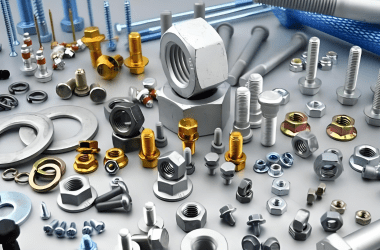

Wuxi Lingdao Automation Technology is an enterprise engaged in the research and development, manufacturing, and external sales of various furniture hardware accessories, focusing on two core businesses of furniture hardware and decorative hardware. The product system covers ball bearing slides, hinges, cabinet brackets, etc. The company has advanced automated production lines and quality control systems. We have strict requirements from hardware molds to product production to ensure the stability and reliability of product quality. At the same time, according to the OEM requirements of customers, traditional processes are combined with modern production processes, new molds are developed, various hardware components are produced, and more high-end and fashionable hardware products are created for customers. This has earned our company recognition from many customers and our products are exported to various parts of the country, as well as Europe, North America, Southeast Asia and other regions.

Clamps are a must-have in woodworking, providing secure holding power for cutting, gluing, drilling, and assembling wood. They ensure precision and safety, whether you're crafting furniture, joining pieces, or working on intricate designs. From simpl...

Hose clamps are vital for securing and sealing hoses in industrial equipment, ensuring leak-free connections in hydraulic, pneumatic, and fluid transfer systems. Their durable design and easy installation make them ideal for factory machinery, produc...

U-bolts are the go-to choice for securing pipes with unmatched stability and durability. Their robust design ensures long-lasting performance, while easy installation saves time and effort. Ideal for various pipe sizes and materials, U-bo...

24

2025-03

24

2025-03

Are you tired of scrambling through the installation process, fixing parts and operating tools? Do you yearn for an artifact that will free your hands and improve installation efficiency? Now it will all be a reality! We are introducing a new product...

More Detail 12

2024-12

12

2024-12

As a company committed to providing customers with high-quality hardware fasteners and services, Wuxi Lingdao AutomationTechnology Co., Ltd. knows that you may encounter various questions in the process of purchase and use. To this end, we have sorte...

More Detail 22

2024-10

22

2024-10

In October 2024, in order to enhance team cohesion and stimulate the fighting spirit of employees, Wuxi Lingdao AutomationTechnology Co., Ltd. successfully held a group building activity with the theme of "Forge ahead at the right time, live up to yo...

More Detail