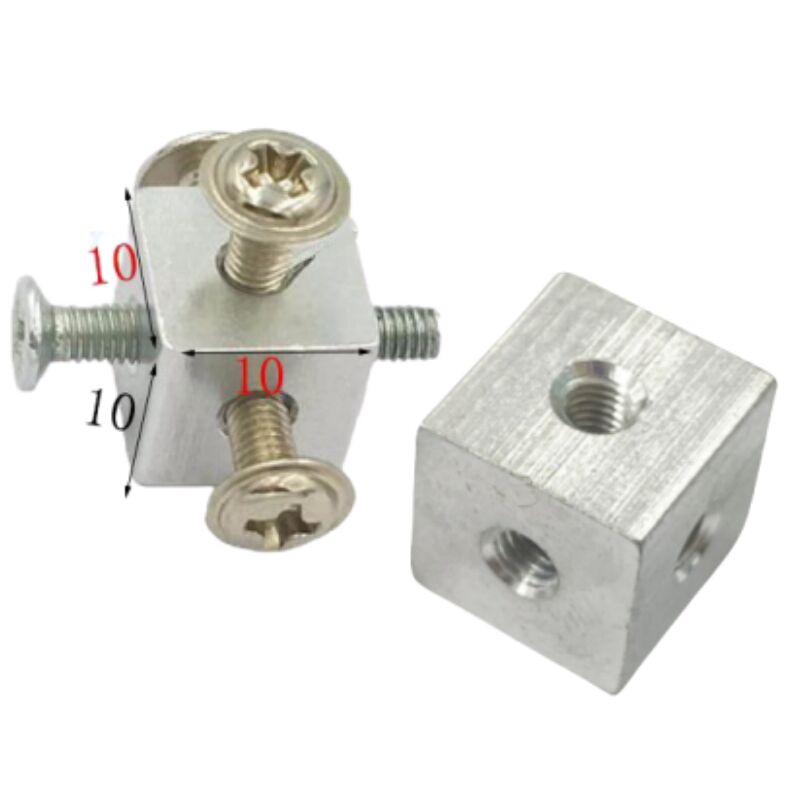

block nut

A block nut is a specialized fastening component designed to provide secure and reliable connection points in various mechanical applications. This essential hardware piece features a rectangular or square-shaped body with a threaded hole running through its center, allowing for precise alignment and robust load distribution. Block nuts are engineered to offer superior stability and resistance to vibration, making them ideal for heavy-duty industrial equipment, manufacturing machinery, and construction applications. The unique design of block nuts incorporates multiple contact surfaces that enhance grip strength and prevent loosening under dynamic loads. These components are typically manufactured from high-grade materials such as carbon steel, stainless steel, or brass, ensuring durability and corrosion resistance. The block nut's geometric configuration enables it to be easily integrated into sliding systems, linear motion applications, and modular assembly structures. Their versatility extends to various industries, including automation, robotics, and precision engineering, where they serve as crucial connection points for rails, guides, and structural components.