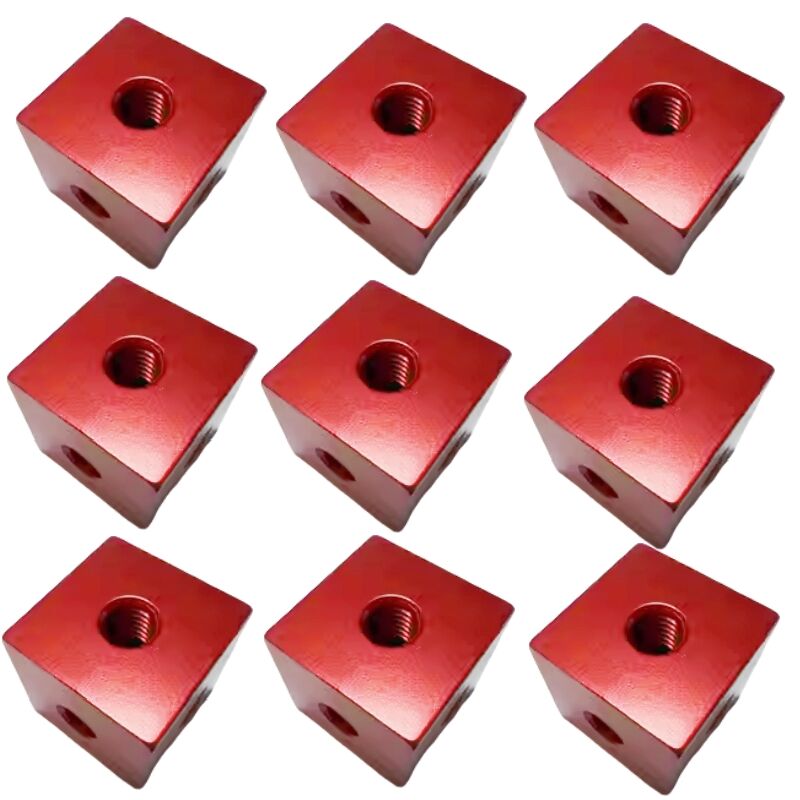

cube nut

A cube nut, also known as a square nut, is a specialized fastening component designed with a distinctive cubic shape that provides enhanced stability and grip in various mechanical applications. This essential hardware component features a threaded hole through its center, allowing it to be paired with corresponding bolts or screws. The cube nut's unique geometric design offers superior resistance to rotation and loosening compared to conventional hexagonal nuts, making it particularly valuable in applications where vibration resistance is crucial. Manufactured from various materials including carbon steel, stainless steel, and brass, cube nuts come in different sizes and thread patterns to accommodate diverse industrial needs. Their flat surfaces provide excellent contact area with mounting surfaces, ensuring even pressure distribution and preventing damage to joined materials. The cube nut's design also facilitates easier automation in assembly processes, as their consistent shape allows for precise positioning and handling by automated equipment. These nuts are widely used in machinery manufacturing, construction equipment, automotive assemblies, and heavy industrial applications where secure fastening is paramount. Their robust construction and reliable performance make them an integral component in maintaining structural integrity and operational safety in numerous mechanical systems.