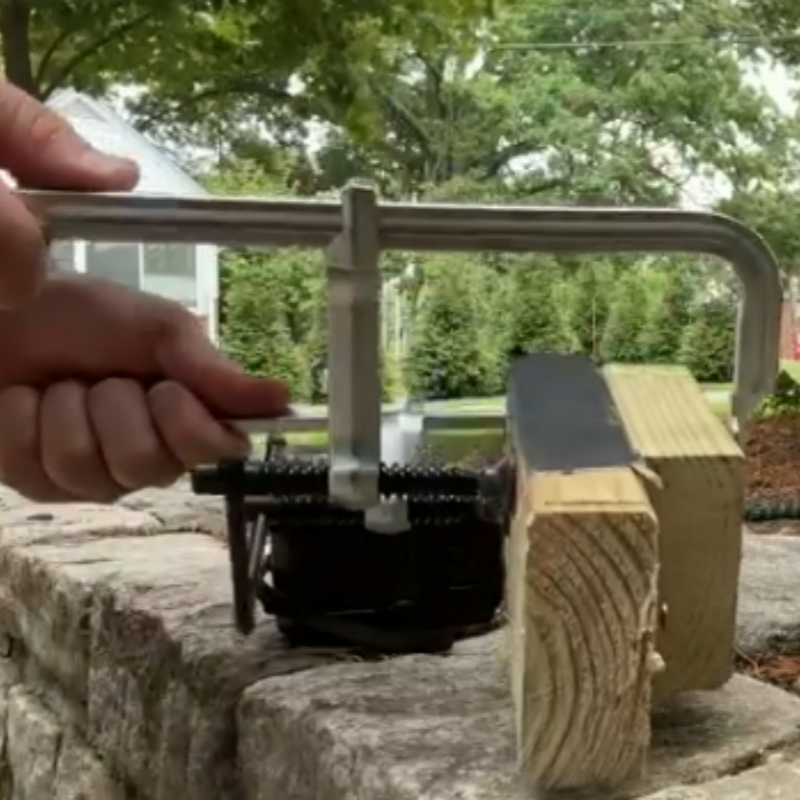

ideal stainless steel hose clamps

Stainless steel hose clamps represent the pinnacle of secure fluid connection technology, engineered to provide reliable and lasting performance in demanding applications. These essential components are crafted from high grade 304 or 316 stainless steel, offering exceptional resistance to corrosion, extreme temperatures, and chemical exposure. The clamps feature precision engineered worm gear drives that ensure uniform pressure distribution around the entire circumference of the hose, preventing leaks and maintaining seal integrity. The screw mechanism incorporates rolled threads for smooth operation and enhanced durability, while the band edges are carefully rounded to protect the hose material from damage. These clamps are available in various sizes, typically ranging from 8mm to 160mm in diameter, making them suitable for a wide array of applications. The robust construction includes a one piece housing design that eliminates weak points and ensures consistent performance throughout the clamp's service life. Advanced manufacturing processes ensure precise band perforations that maintain strength while allowing for smooth adjustments.