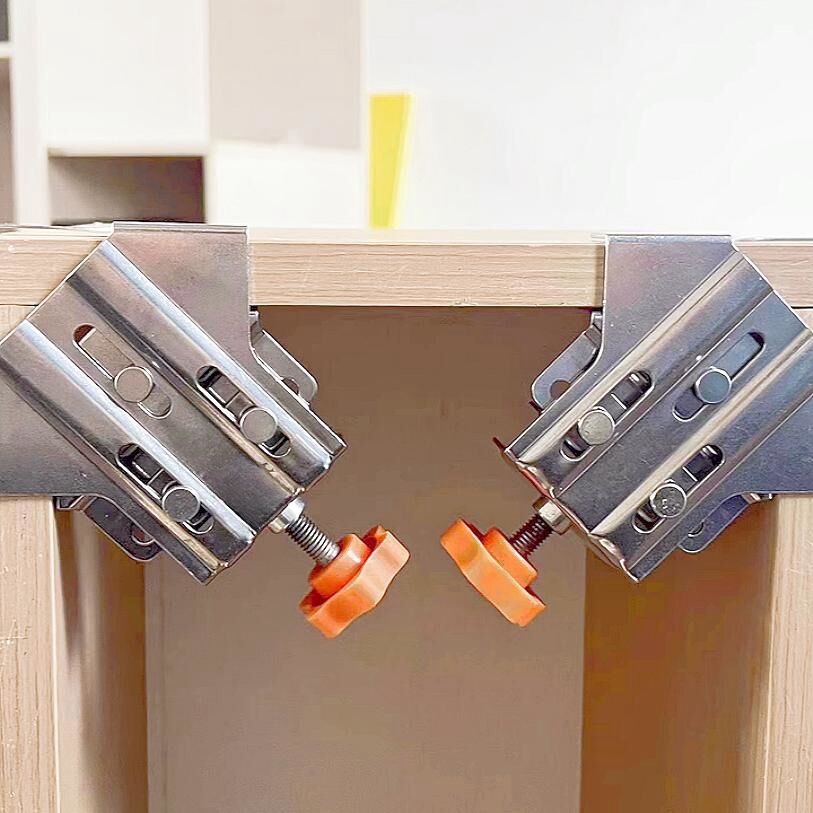

wood c clamps

Wood C clamps are essential woodworking tools designed to provide secure and reliable holding power during various woodworking projects. These versatile tools feature a C-shaped frame made from durable materials, typically cast iron or steel, with two parallel jaws, one fixed and one adjustable. The adjustable jaw is controlled by a threaded screw mechanism that allows users to apply precise pressure to hold workpieces firmly in place. Modern wood C clamps come in various sizes, ranging from small 2-inch models for delicate work to large 12-inch versions for heavy-duty applications. The clamps feature protective pads on the contact surfaces to prevent marring or damage to the workpiece, while the ergonomic handle design ensures comfortable operation during extended use. These tools excel in applications such as gluing, assembly, and holding pieces steady during cutting or drilling operations. The robust construction ensures long-term durability, while the precision-engineered threading system provides smooth operation and consistent clamping pressure. Wood C clamps are particularly valued for their stability and ability to maintain constant pressure over extended periods, making them indispensable for complex woodworking projects that require extended curing times for adhesives.